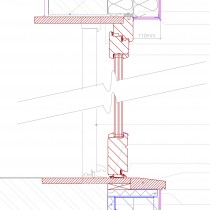

Section detail for a new replacement door with a timber frame box to the existing door reveal installed into existing External wall insulation works; (or installed as part of EWI works: but with insulation installed before door.)

The new door is installed in a softwood box frame, glued or fixed to the new door frame; to the size of the existing opening, in order to replace the existing door. The new door and box frame means the door sits further into the EWI; bringing the door into the buildings thermal envelope, eliminating the need to insulate the existing opening, and therefore reduce thermal bridging around the existing opening.

The door threshold is reinforced with steel angle for structural support, with additional structural insulation over extruded polystyrene suitable for below ground insulation.

View detail →